Printed corrugated boxes protect products while also acting as ambassadors, proudly showcasing the brand messaging and product benefits. Different types of printing options are available, so how do you know which is best for your business?

Each printing option has pros and cons that are better suited to different businesses depending on the order volume, budget and design complexity. Read on to find the perfect printing type for your corrugated cardboard boxes.

Corrugated cardboard is a multilayer material made of thick paper stock or heavy paper pulp. The corrugated layer is known as the flute, and it’s arranged in different patterns to help it hold its shape better. It’s strong and durable, making it bump-resistant and keeping it intact during rough transits. Four main types of corrugated cardboard are used in packaging:

Different designs, uses and colors call for specific methods. It’s important to understand the types of printing on corrugated boxes to make the best choice. Here are the three common methods for printing on corrugated boxes:

Flexographic printing uses flexible rubber plates that are mounted on a cylinder to create an impression on the material. This process enables the machine to deliver quality prints in high volume using a wide range of inks. Flexographic printing is ideal for corrugated carton printing with simple designs.

Pros:

Cons:

Lithographic printing, also known as litho printing, is a popular process for printed corrugated cardboard. It’s used for printing vibrant graphics on product boxes that need to stand out in high-traffic areas. Typically, the process involves placing the desired artwork on a plate covered in ink, and the material positioned on the image rapidly absorbs the ink. This process is known as offset printing.

Pros:

Cons:

Digital printing is a direct-to-surface technique that’s the preferred method for cardboard and coated boxes. It reproduces electronic images onto the desired material. Unlike the other printing methods that call for plates and other steps, digital printing uses technology like laser or inkjet to print directly from digital files.

Pros:

Cons:

Direct printing is printing directly onto the corrugated box, while pre-printing involves printing onto a separate material and then applying it to the box. If you’re trying to decide how to print on corrugated boxes, here’s a table to make the process easier:

| Direct Printing | Pre-Printing |

| More cost-effective, especially for smaller runs | Becomes more cost-effective with bulk orders |

| Quicker turnaround because it prints directly on the corrugated box | Longer lead times because you need to attach and laminate the substrate |

| Prints clear and vibrant designs | Ideal for ultra-vibrant, premium prints |

| Better pick for personalized print information, like unique codes | Not the best option for variable data printing |

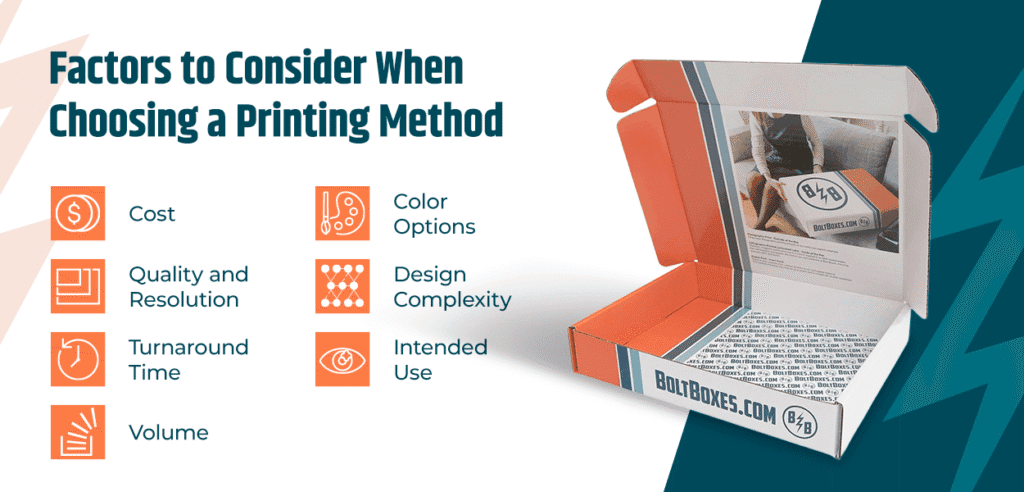

Corrugated boxes are a crucial part of brand image, and it’s important to choose the printing method wisely. Here are the top factors to consider when deciding:

Flexographic printing is the most cost-effective method. It prints directly on the box and only calls for a one-time investment in print plates.

Flexographic printing can process up to 12,000 sheets per hour and create high-quality images. It’s typically used for subscription, bakery and shipping boxes.

If you need high-detail images, then lithographic or digital printing may render the best results. Flexographic prints can also provide vibrant images for minimalist designs. Choose a print method that can create your desired image quality.

How quickly do you need the boxes? If speed is one of the most crucial factors, choose a method that allows for quick, high-quality graphics, like flexographic printing. Businesses offering personalized prints should choose an option that can make speedy revisions, like digital printing.

If you’re looking for short-run prints, digital printing might be a good option. For high-volume projects, flexographic printing is a better option. You should also consider the product volume, dimensions and weight when deciding on a printing method.

Bigger packaging would be a better match for direct printing methods, as they have a larger surface area. It would cost more for laminating and have much longer lead times.

Corrugated carton printing offers many opportunities for creativity. Flexographic methods allow for three-color printing, while lithographic printing accommodates up to six colors. Generally, digital printing offers a wider color variety, making it an excellent choice for super colorful artwork.

Simple designs call for fewer colors, which can make them suitable for more cost-effective methods like flexographic printing. More complex designs call for methods like digital printing.

Additionally, consider if there are any legal requirements that would call for warnings, barcodes or nutritional information. In these cases, choose printing methods that create highly detailed images for maximum visibility.

Do you plan to create product packaging for retail use or shipping boxes? Retail packaging needs to be eye-catching to draw shoppers’ attention. Shipping boxes also need to be visually appealing, but they should also be ultra-durable to withstand rough transit conditions.

Finding a reputable box manufacturing company involves aligning your business vision with a supplier that can bring it to life. Here are the top factors to consider when making a choice:

At Bolt Boxes, we know how to print on cardboard boxes, but it goes beyond that — we know how to make an impact through custom packaging. We have over 60 years in the packaging business, and our expertise shows in our 99% on-time success rate and our raving testimonials from satisfied clients. We are ISO 9001:2015- and G7-certified and offer unmatched customer service.

Our custom boxes are made from 100% recyclable corrugated cardboard, offering you packaging that protects your products and the environment. As the fastest box manufacturer in the world, we have no doubt that we can help you meet your deadlines.

Do you want to increase positive brand perception through high-quality, durable and visually appealing packaging? Contact us today for packaging that ticks all the boxes.