In recent years, the packaging industry has shifted its focus from convenience to sustainability and eco-friendly practices. New and emerging technology has influenced the latest packaging trends. This article details the future of packaging and what it can offer your business.

As more companies rely on service providers to create custom product boxes, third-party packaging manufacturers have become mainstream and highly sought after. The result of this is:

Below are some possibilities for the future of the packaging industry:

Design trends gradually change as companies find innovative ways to compete for customers’ attention. Each year, changes in everything from the most used color schemes to packaging styles are common. Personalized designs are more than a trend, however. Custom packaging is highly effective and rarely goes out of style.

Smart packaging designs offer an improved fit, superior protection for your products and better overall structural support. Customized packaging is also a valuable marketing tool, allowing for a uniquely professional look. Customers appreciate the experience of getting unique product boxes with dynamic designs.

More companies are switching to sustainable materials to be more eco-conscious in their approach to packaging and products. Consumers are more green-conscious than ever with the rising awareness about climate change and single-use items taking up too much landfill space. Using sustainable and reusable materials like cotton, paper and recyclable synthetic fibers sends the message that your company takes its responsibility to improve the environment seriously.

Use printing options on custom packaging to suggest ways for customers to reuse your boxes and packing materials. Encouraging buyers to reuse what you send their products in also demonstrates your business’s focus on sustainability.

Automation has been around for a while, but once COVID-19 happened, employers experienced a need for solutions that would keep their businesses running without employees working in person. Automation can increase your business’s production speed without sacrificing quality. Automation technology reduces the need for human intervention in manufacturing while still allowing humans to supervise the process.

Machine automation has many benefits for the packaging industry, including:

Artificial intelligence (AI) technologies have improved the operations aspect of packaging manufacturing in recent years and are continuing to advance. New programs keep coming up, along with plenty of startup technology companies offering third-party services. Blockchain technology allows you to record your transactions or track your assets automatically. These advancements are relatively new for the packaging industry but have quickly raised standards in their brief history.

Having AI process your data means fewer errors that can result in setbacks. The most advanced AI programs can now detect and prevent errors before they occur using a visual inspection program. This technology has progressed so quickly that it will likely become commonly used in commercial industries.

Interactive packaging can serve many important functions, including making information easier for customers to find. Interactive packaging can also be entertaining, especially when it offers a creative approach to marketing that customers appreciate.

You can make your products interactive by:

Relying on eco-friendly packaging practices involves selecting sustainable materials or cutting down on materials that are more problematic for the environment. For example, plastic particles have accumulated over time, leading to serious, widespread ocean contamination.

This has led many companies to start relying on alternative packaging materials. Manufacturers have developed new materials like:

Consumers’ demand for eco-conscious business practices and the renewed drive to improve the environment of the future has led companies to make eco-friendly choices. Many consumers are willing to pay more for sustainable products from companies with eco-friendly values.

Eco-friendly packaging generally comes with helpful customization options for the size, style and printing. Custom fitted boxes reduce your need for packing and other filler materials, leading to less waste ending up in landfills.

Augmented reality (AR) technology used to be considered futuristic but has progressed quickly after its implementation in commercial industries. An AR feature is simple to set up by simply printing a QR code onto a product box or custom packaging.

When your customers scan the QR code, they are directed to your website, media channel or another webpage where you can store product information or other features. AR then integrates animations or images with your packaging to bring the product to life. The best part of using AR is that you can update your website without redesigning your packaging.

AR can be used for many creative and practical functions, including:

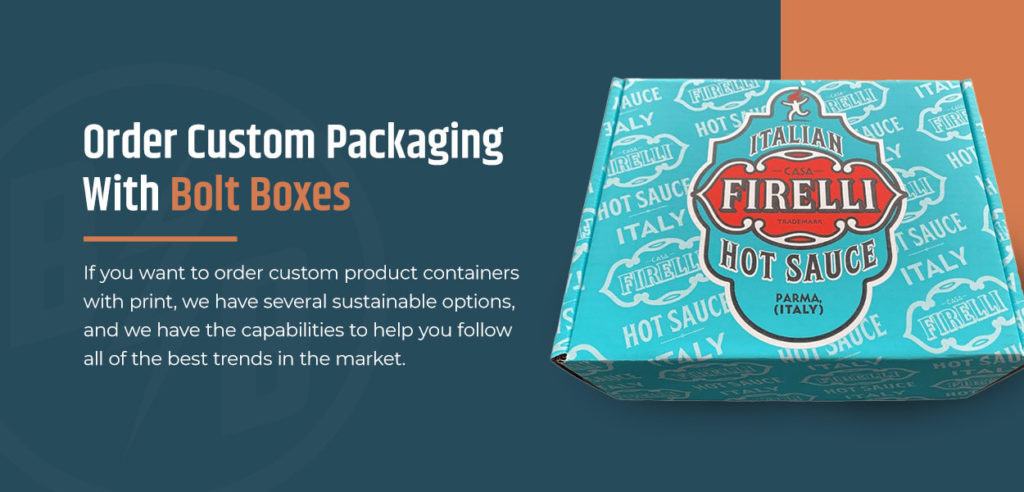

Bolt Boxes produces a variety of high-quality product packaging solutions. If you want to order custom product containers with print, we have several sustainable options, and we have the capabilities to help you follow all of the best trends in the market. Contact us for a quote today.

Check out related articles: