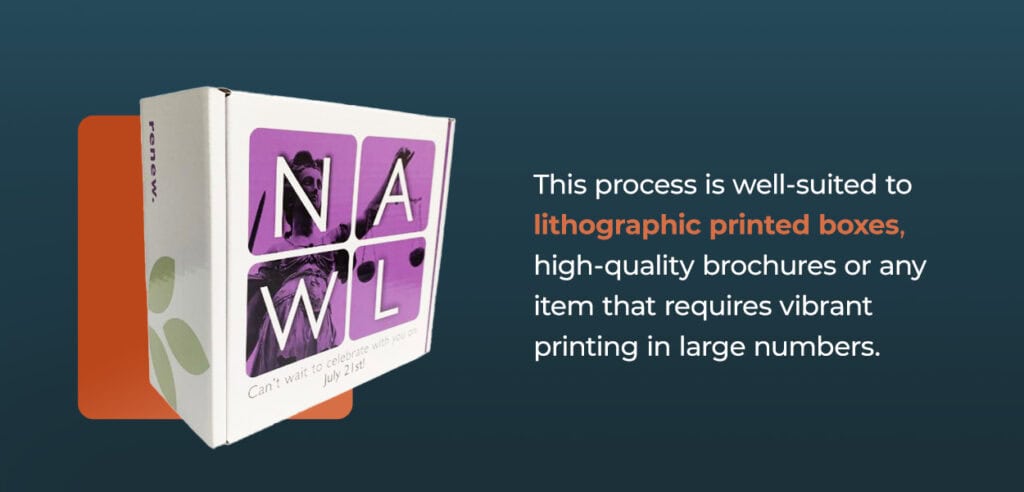

Lithographic printing produces sharp, vibrant and exquisitely detailed images. When using custom packaging to boost brand identity and create shareable unboxing moments that stand out in a competitive market, custom litho-printed boxes are a beautiful way to convey your values, tell your brand story and build customer loyalty.

Unlike direct ink-to-substrate flexographic printing, litho printing prints an image on paper and then laminates it onto packaging material. Ink is applied to a printing plate and transferred to a rubber blanket before it is passed on to the printing box, which is why it’s sometimes called “offset printing.”

Learn more about lithographic printing for packaging and how it can benefit your business.

Custom boxes are, in essence, mobile billboards. Inside and out, they offer a high-profile space to communicate with your customers. What makes a bigger impact than crisp words, vivid images and the joy of anticipating what’s inside?

The journey to unboxing begins with design and layout.

First, the plate creation process entails two key steps:

Getting the color process just right comes next:

The plates are now ready to be prepared:

Now, the magic begins:

The final stage includes a two-step transfer:

Lithographic printing can produce sharp images, print on different materials and offer customizable finishes, making it a popular choice for brands that want to make an impression. Here’s a closer look at the advantages:

When choosing the right printing method for your business needs, consider cost, volume, quality and speed, as they apply to litho, flexo and digital printing.

This planographic printing method uses inks, aluminum plates and rollers to produce vibrant, high-definition imagery. Key factors to consider are:

High-speed, roll-feed flexography is a popular choice for these reasons:

When deciding whether to choose this method of printing digital-based images directly onto a substrate, take into account:

With corporate sustainability initiatives and a shift in consumer buying decisions, turning to plastic-free packaging alternatives is a popular trend that’s here to stay. Custom shipping boxes are an ideal solution for many companies.

Tailored to the specifications of your product, they reduce the need for fillers, allow the packages to reach your customers safely and also eliminate unnecessary waste. Manufactured from responsibly sourced or biodegradable material, custom boxes reduce environmental impact and enhance your brand image. At Bolt Boxes, we are SFI® Certified and manufacture our boxes with 100% recyclable kraft boxes.

The personalized packaging market is constantly changing. Keeping up with custom packaging trends can set your products apart in a crowded marketplace. We have been helping businesses elevate their packaging for almost 60 years.

Contact us today to discuss how litho printing can elevate your brand story, or build your box online to receive a free quote in five simple steps.