When your business ships a product to a customer, the packaging is the first thing they see. Many companies and organizations, such as Amazon and Apple, use their packaging to enhance branding. For example, the Amazon “smile” logo is immediately recognizable to customers. Apple, on the other hand, uses sleek white packaging to stand out.

The color of the boxes you choose can help customers identify your brand and even enhance their perception of your products. However, making the choice between classic kraft boxes and white boxes can be difficult, as both have unique benefits that make them appealing.

That’s where we come in. Our packaging guide will walk you through the basics of kraft corrugated boxes vs. white corrugated boxes so you can invest in the one that aligns with your business’s style.

Packaging with kraft boxes has been an industry standard for decades. They’re tough, versatile and reliable for both consumers and businesses. Other pros include:

These boxes are not without their limitations, however. Consider some potential downsides of kraft packaging:

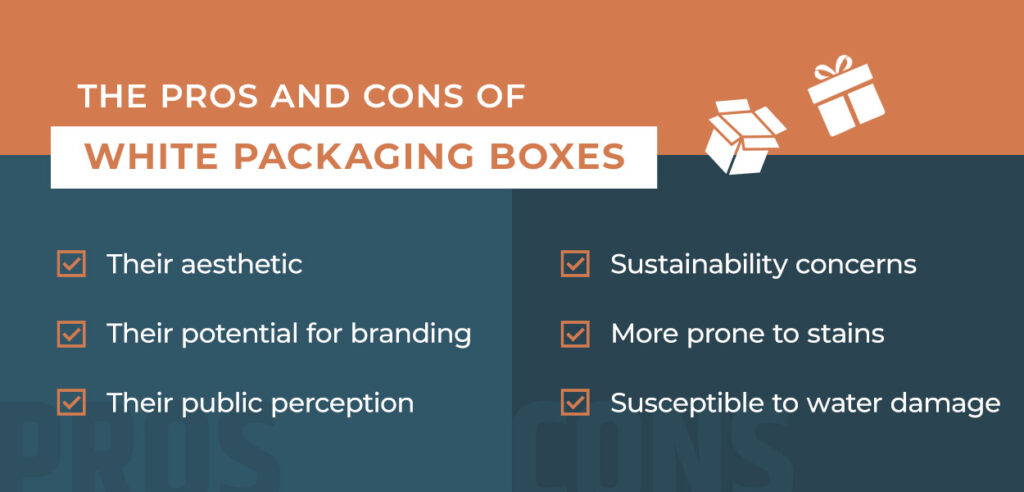

Using white cardboard boxes for packaging is a less common practice, and that is part of the appeal. Most people expect to receive a brown box on their doorstep when they order something. When a white one shows up instead, the experience becomes more distinctive and memorable, especially if the box leverages the branding options afforded by the white color. Other upsides of white packaging boxes include:

There are some downsides to using white packaging:

Whether you use white boxes or kraft ones, you need a beautiful, functional design that communicates who you are to your customers and the market at large. With Bolt Boxes, you can do just that. Our turnaround times are the fastest in the industry because we’ve been designing, manufacturing and shipping boxes for over 60 years. Our in-house structural designers will work closely with you to ensure your boxes are shaped for your products, and our G7 Master Qualification ensures our prints are of the highest quality.

To learn more about partnering with us, fill out our contact form or give us a call!