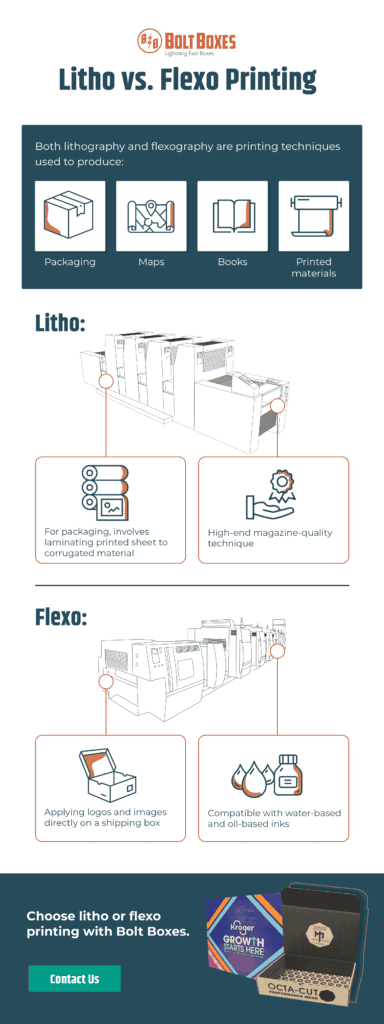

Both lithography and flexography are printing techniques used to produce packaging, maps, books and other printed paper materials. While each method is used for a different purpose, each has its upsides and downsides regarding cost, quality and function. Read on to discover the differences between litho and flexo printing and learn when to choose one over the other.

Table of Contents:

Litho printing stands out from flexo, digital and other techniques in that it involves laminating printed sheets on top of your mailing box. Instead of directly applying color to shipping boxes via stamping, litho printing is a two-step process that consists of applying ink to a printing plate before transferring it to a rubber blanket. From there, the ink is passed on to the printing box.

The second process used for box printing is lithographic lamination. The print is first made on paper and then laminated on the box for a premium, glossy finish.

Modern litho printing is a high-end, magazine-quality technique that uses an offset process. In fact, it’s the go-to technique for vibrantly colored printing in large quantities.

Flexography is a high-volume, reliable printing process that involves applying logos and images directly on a shipping box. Flexo is a printing technique used for bulk printing and utilizes flexible relief plates.

A flexographic printing process uses an anilox roll to distribute ink onto a printing plate.

If your media is mostly flat, litho printing may be the way to go. It’s also best for designs that have intricate details and photographs that call for full-color prints. Litho printing works best on paper and flat cardboard mailing boxes.

Other benefits of lithographic printing include that it:

One of the most significant advantages of using flexo printing is that it works on a wide range of substrates — non-flat media included. Flexographic printing is an ideal choice when you’re dealing with a minimalistic design with bright, solid colors. Other reasons to choose flexo over litho printing follow: